Flexible transparent conductive electrodes (TCEs) have recently received much attention from both academic community and industrial sectors due to the rapid development of rollable or foldable displays. Metal-mesh TCE is particularly attractive because it exhibited extremely low sheet resistance at high optical transmittance and good mechanical flexibility among all kinds of flexible TCEs, such as ITO, grapheme, carbon nanotubes, metal nanowires, conducting polymer, etc. However, most of metal-mesh TCEs have a common feature in their fabricated method, i.e. the metallic lines are made on the surface of substrate, which is fine for touch panel applications but problematic when used for optoelectronic devices.

Recently, Prof. Cui Zheng's group in the Suzhou Institute of Nano-Tech and Nano-Bionics (SINANO), Chinese Academy of Sciences, has fabricated an extremely smooth Ag/Ni metal-mesh TCE with the surface roughness of 0.17 nm. Related results were published in ACS Applied Materials & Interfaces under the title “Embedded Ag/Ni Metal-Mesh with Low Surface Roughness as Transparent Conductive Electrode for Optoelectronic Applications”.

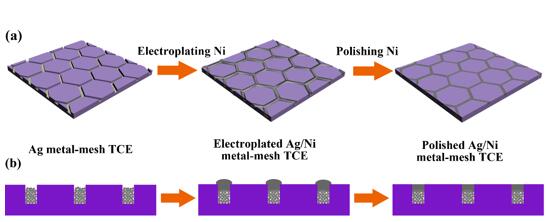

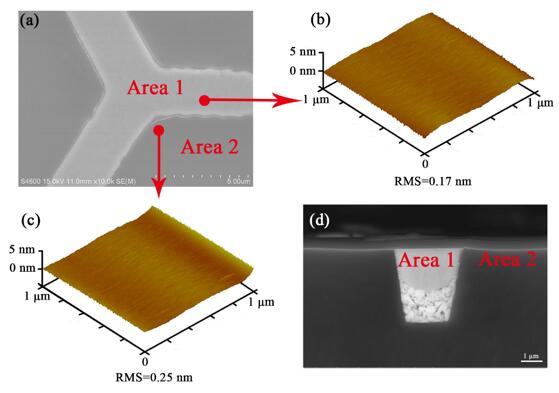

In this work, a new method to make highly flat metal-mesh TCEs is presented. Instead of a full filling of the trenches with Ag ink, the trenches are partially filled and then electroplated with Nickel (Ni). The slightly over plated Ni mesh lines are polished back to create a highly smooth surface with roughness of only 0.17 nm (Figure 1 and Figure 2). As shown in Figure 2d, there is no gap or step between the polished metal Ni lines (Area 1) and the nonconducting region (Area 2). The polished Ag/Ni metal-mesh TCEs achieved high conductivity with 2.1 Ω/□ sheet resistance and 88.6% optical transparency.

The flexibility by bending test and environmental stability are further studied. The results exhibit Ag/Ni metal-mesh TCE has good mechanical flexibility and environmental stability at high temperature and humidity. The polished Ag/Ni metal-mesh TCE is applied for the flexible quantum dot light emitting diodes (QLED), which presents an efficiency of 10.4 cd/A and 3.2 lm/W at 1000 cd/m2. This work is very helpful for metal-mesh TCE to avoid electrical short-circuits or current leakage in optoelectronic devices.

This work is supported by the Strategic Priority Research Program of the Chinese Academy of Sciences, the National Program on Key Research Project, Science Foundation of Two sides of Strait, Program on Key Research Project of Jiangsu Province of China and Youth Innovation Promotion Association.

Figure 1. (a) Schematics for fabrication process of Ag/Ni metal-mesh TCE; (b) Schematics of cross profiles about metal-mesh TCE.

Figure 2. (a) SEM images of Ag/Ni metal-mesh TCE after polishing Ni; (b) AFM image of polished Ni on Ni metal-mesh TCE; (c) AFM image of the unconducting region on Ag/Ni metal-mesh TCE; (d) Cross-sectional SEM image of Ag/Ni metal-mesh TCE.

Reference: http://pubs.acs.org/doi/10.1021/acsami.7b11779